What’s So Crucial About Warehouse Design Planning

Every leading architect will tell you that planning and running a warehouse is science mixed with fine art. It requires time, understanding, and energy. For both warehouse businesses and those who need a warehouse of their own, the design is crucial. The layout and plan of it directly impact the business by affecting operations, manufacturing, assembly, and efficiency.

It is why the design has to be considered before building a warehouse. While there is no one correct method for planning a warehouse, there are some strategies that benefit a business. In this post, we discover some proven tools for designing a warehouse for better business.

Begin From Within And Create Aisles In The Warehouse

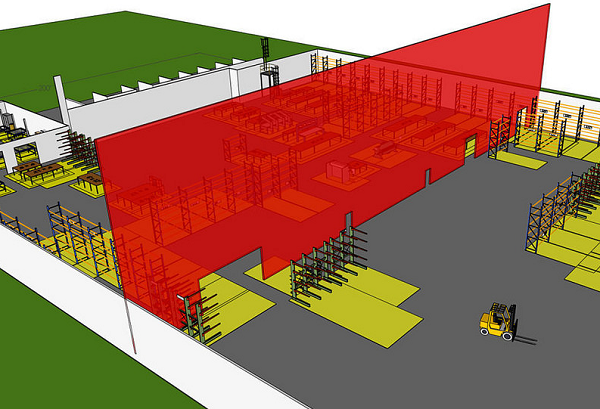

Racks and shelves make or break a warehouse. Therefore, start with designing the inside of the warehouse first, i.e., what the racking system will be. The right racking system significantly impacts picking efficiency, container handling, and other operations. It is why planning the storage capacity and how items will be stored is the first step. Once that is done, the outer part of the building can be designed. Check Out – The layout planning tips of a warehouse design.

Racks and shelves make or break a warehouse. Therefore, start with designing the inside of the warehouse first, i.e., what the racking system will be. The right racking system significantly impacts picking efficiency, container handling, and other operations. It is why planning the storage capacity and how items will be stored is the first step. Once that is done, the outer part of the building can be designed. Check Out – The layout planning tips of a warehouse design.

To get the right racking system, aisles and shelves of the warehouse are crucial, as they allow finding goods easier. Plus, transferring them from point 1 to point 2 becomes faster. How do you plan aisles? By keeping these points in the fore-front:

- Do not make them too long. Long aisles may help save on space, but in the long run, they make it harder to pinpoint the location of items. It ultimately slows down operational capacity.

- Short aisles in crosses are a better method as they optimise the operations and efficiency of the warehouse.

The next step to warehouse design planning is using structural steel. It is the one material that makes perfect sense for all structures inside the warehouse and outside.

The Entry And Exit Planning Along With Future Vision

The racking system, the kind of aisles, and the material used to make practical structure are the fundamental elements of effective warehouse planning. An equally important part is the doors. It may seem like a fool’s task to ponder over doorways, but it is essential. The wrong door can hinder the fast movement of goods. Some questions to answer are:

- Is it an entry or exit door? Where is it placed?

- Does it require insulation to protect products?

- Will it see heavy traffic?

A tip is to keep the shipping door and receiving door at two separate sections of the warehouse. It ensures that the production zone and shipment zone are clearly demarcated and no errors arise.

The features we’ve spoken about till now help design the warehouse in the current time, but every business has to be planned with the future in the sights. For a warehouse, it means automation. Technology is fast changing how warehouses work. Thus, it behoves a businessperson to plan a warehouse with automation in mind. From material handling equipment to cobots, think what machines you may use in the future and then plan the warehouse accordingly.

The features we’ve spoken about till now help design the warehouse in the current time, but every business has to be planned with the future in the sights. For a warehouse, it means automation. Technology is fast changing how warehouses work. Thus, it behoves a businessperson to plan a warehouse with automation in mind. From material handling equipment to cobots, think what machines you may use in the future and then plan the warehouse accordingly.

A simple example is building a multi-floored warehouse with proper flooring, then consulting leading architects with knowledge of automated solutions would be a smart idea. They can help answer imperative questions such as how will the forklift or pallet jack move from one floor to the other?

Overhead space, what you are storing, what is moving out of the warehouse every day vs. what stays on the shelves longer, what type of shelves to use, how will the assembly area work, the list of factors while designing a warehouse are many. Modern warehouses hardly resemble the storage spaces of past times.

Building them is a complex task that necessitates proper guidance and in-depth knowledge. Applying ideas shared above may help, but roping in leading warehouse architects for the design would be a better option.